Around here, you can get aluminium corner lengths of 1 meter at the local home improvement shop (gamma, karwei, hornbach, etc).

They are 10mm high and wide and the wall thickness is around 1.5 mm.

Also available is aluminium tubing with a diameter of 10mm and 10mm wide strips.

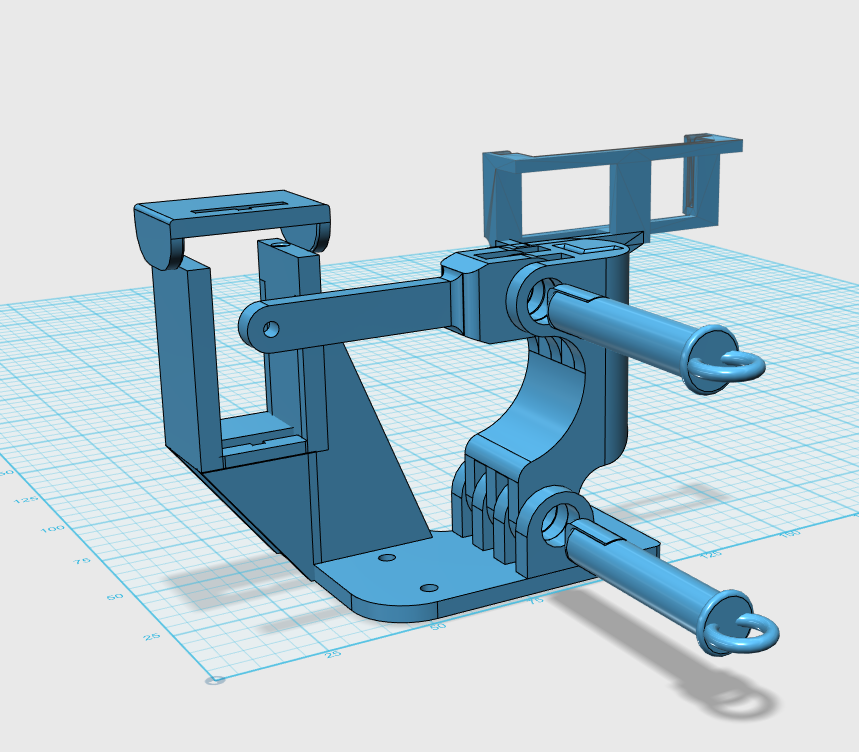

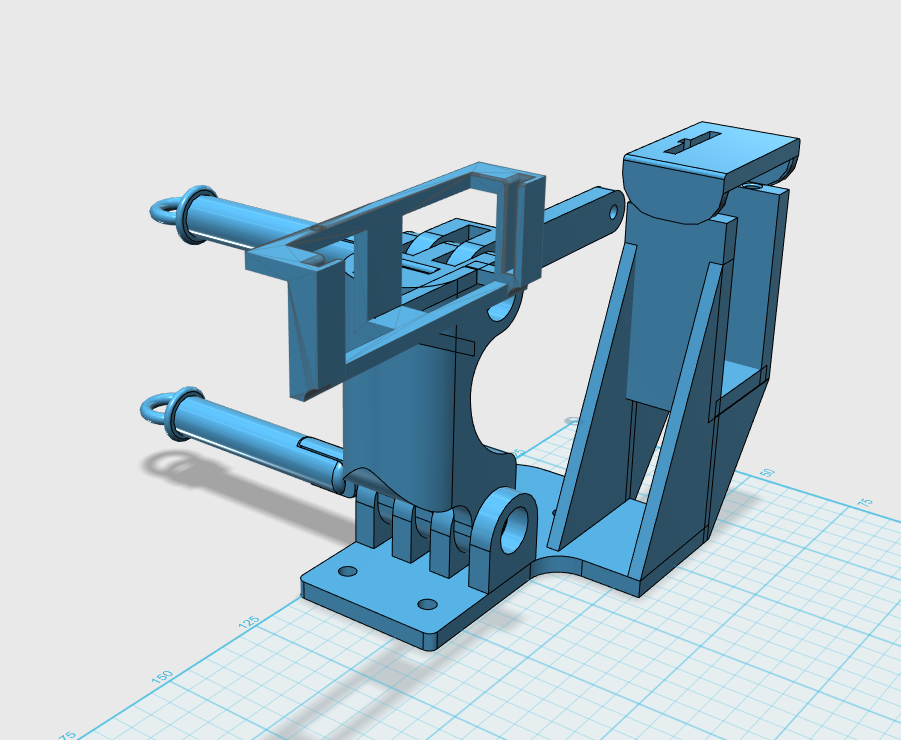

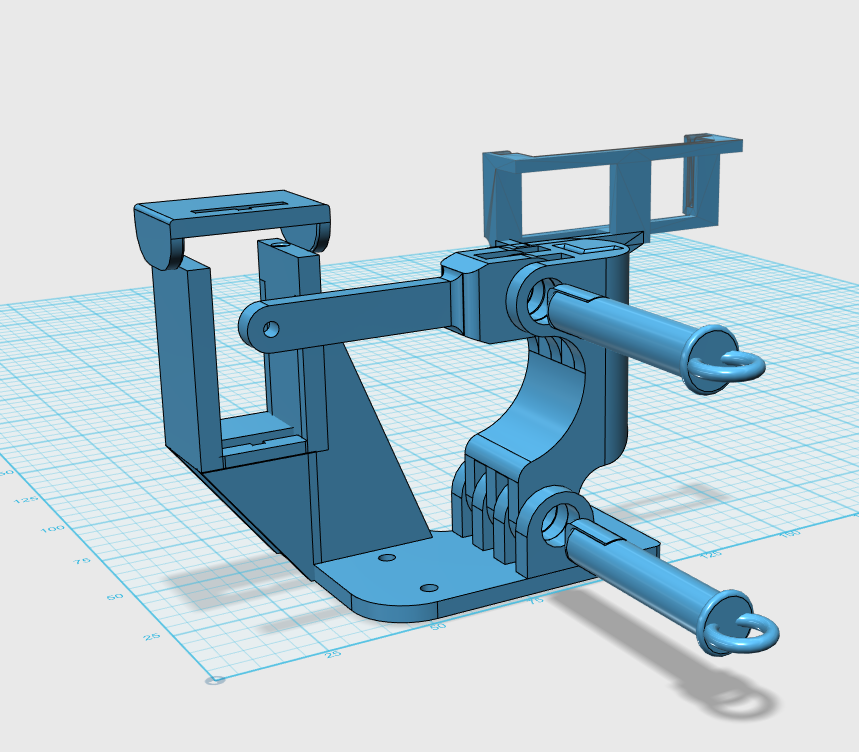

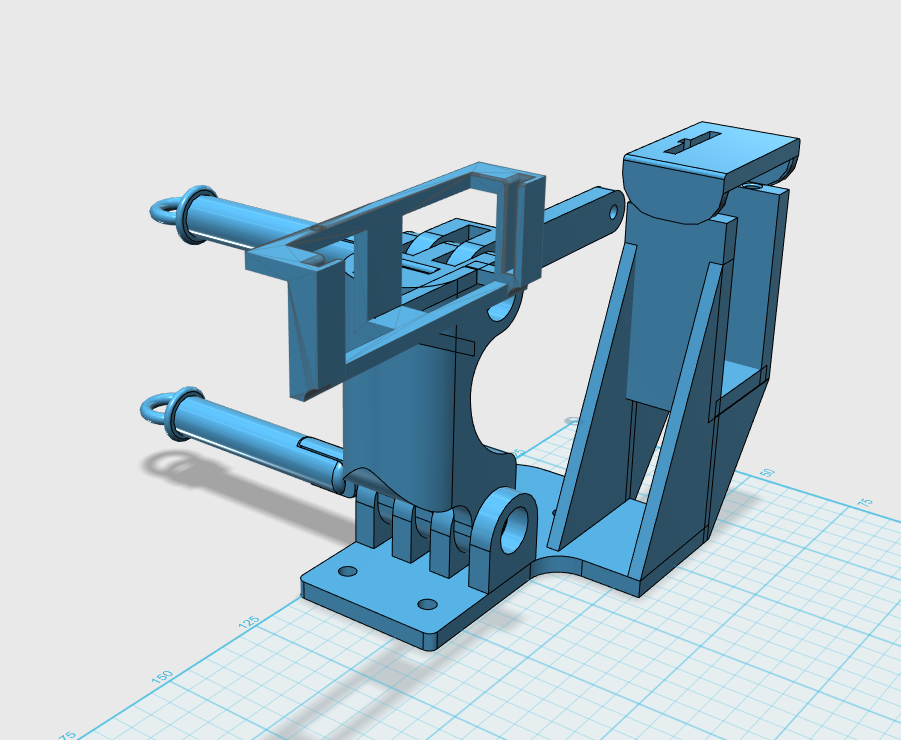

The hinge is constructed by 3d printing it.. This has to be able to come apart easy so the swingarm is detacheable from the stand and can be easily stored in a box.

The download links for printing the hinge can be found at the bottom of this block.

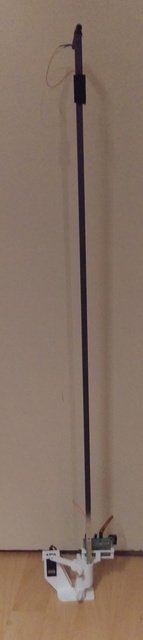

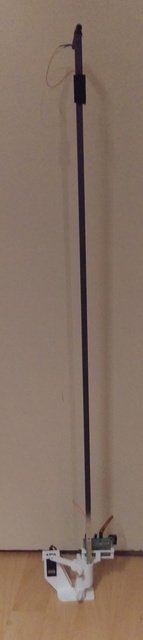

The way things are set up, the maximum swing at the top is just about the same as the length of the arm!

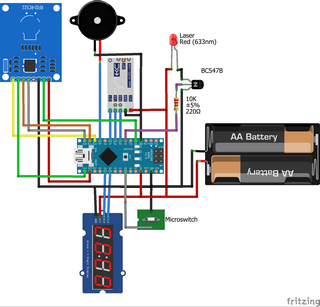

For each target, as i made them, the parts list is:

- 3d printed parts

- 1 baseplate

- 1 servo cap

- 1 top part (with or without the circuitboard holder)

- 1 coupler piece

- 2 pins

- 2 pinlocks

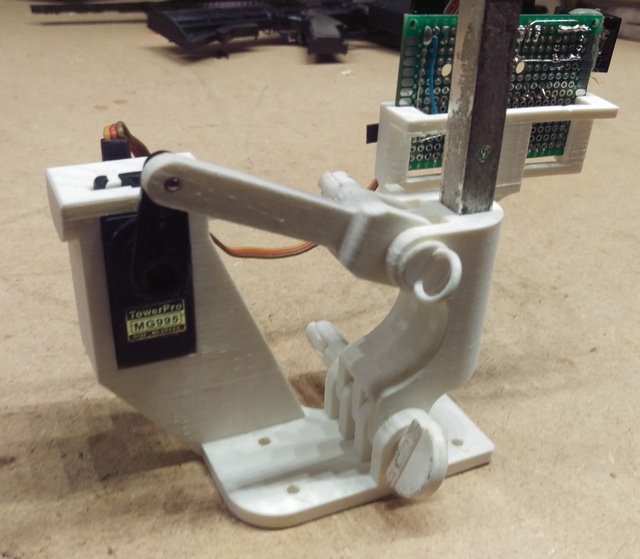

- 1 servo (MG995)

- 1 meter corner length

- 10 cm tube

- 20 cm flat strip

- 2 M3 X 10 bolts with nut

- 1 M3 X 15 bolt with 2 nuts

- loctite

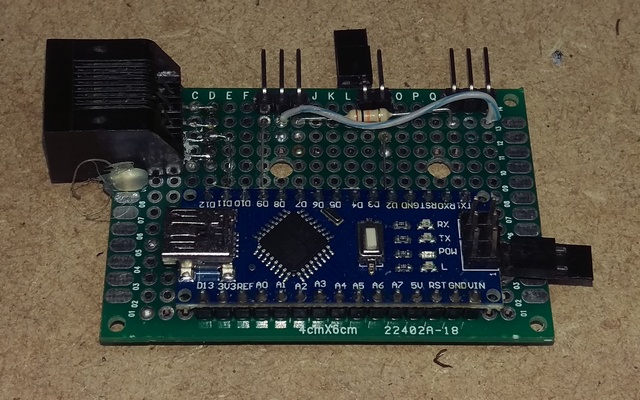

- the circuit board with the target electronics on it. Mine are 60 X 40mm

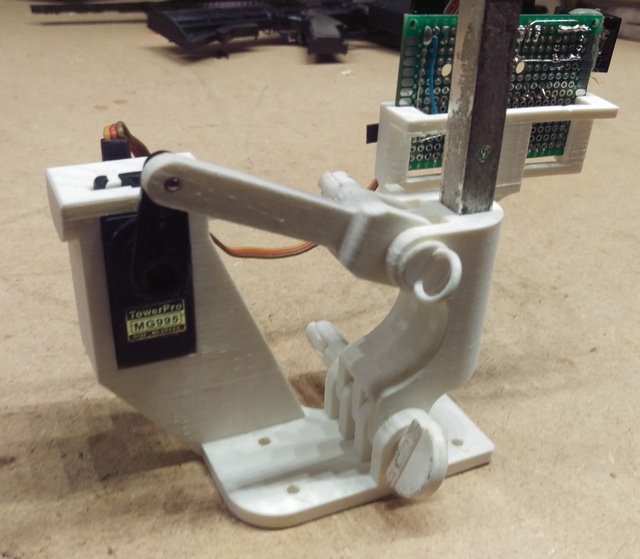

How the hinge fits together can be seen on the pictures:

Remarks on this design:

- The aluminium is press-fitted in the upper hinge part. Put the it in a vice and gently tap the upper part on it with a hammer. It should go in about 5 cm. Do NOT hit the rounded parts (the hinge bits), they will break if you do.

- There are 2 versions of the upper part of the hinge. One is just the part, the other one has a circuit holder attached to it for a circuit board size of 60mm wide. Just one version is needed.

- Make sure to print the upper hinge part upright!! It takes a LOT more support, but there can't be any support in the slot where the aluminium goes in to, you will never get any supports out of there!

- It is stable and solid enough to handle the load, even with the servo at full speed, so no need to have ramp ups etc.

- It comes apart easy using 2 self-locking pins

- The pins have a lock built in. The easiest way to put together the pin is to use a vice and press the small pinlock in the slot over the nudges, or print it in place.

- The size of the pin is intentionally just a bit to large.

- No extra parts needed except 1 M3 bolt for connecting the coupler to the servo arm. First secure the bolt with a nut to the arm of the servo, then put the coupler on and last another nut, locked in with loctite.

- Take care connecting the servo!! If you put the plug wrong on the headers, it will blow up the arduino. For this purpose, a small 'O' is printed on the holder, denoting which side the Orange wire goes.

When putthing things together, make sure you lock the outer nut on the servo arm with loctite so it won't come off, and press the cap above the servo holder on it so it fixes the servo in place with the tabs in the slots top and bottom.

The servo is put in upright with the axle at the top.

To prevent any reflection coming back to the shooter, everything is painted in flat black.

To finish things off, it's fun to put something over the targets/ldr tube. For this some cardboard with a funny face, bullseye or something else on it is painted.

A hole is made for the ldr tube and then it's attached to the arm.

Whatever you do, make sure it's not adding too much weight to the top of the arm.

The finished target assembly:

Yes, the target is balanced so that if it stands upright, it can stand on its own! Ofcourse not when it goes to either side, that is where the holes come in, they can be used to fasten this hinge to a stand.

I didn't do any after-printing finishing at all, it should just fit together and work, with two exceptions: the pin and the pinlock.

The pinlock fits kinda snug, so it's nice if you sand the sides down a bit. After fitting it to the pin, it should not be that loose so it rotates on its own, but you shouldn't need pliers to rotate it.

Also, after installing the pinlock, use some sandpaper to sand the entire pin. The pin fits tight and is intended to be sanded down.

Sand it down just enough so it will fit snug but it isn't hard to place or remove. This will also make the pinlock flush to the pin.

The picture doesn't show a stand because i don't have one. I made a crude one out of some wood, lifting the target about 25cm off the floor, setting the target at about 1.25m high.

Once i made a (foldable!!!) stand, i will add it to this page.

All the files for printing the hinge parts: